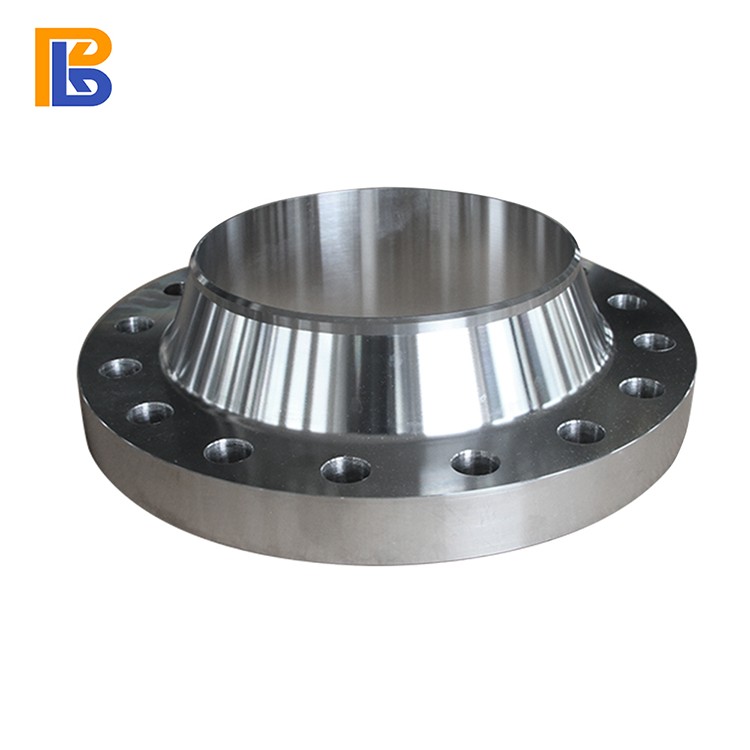

Ring Type Joint Flange

- BOBERRY

- China

- 15-30 Days

- 150-200Tons/month

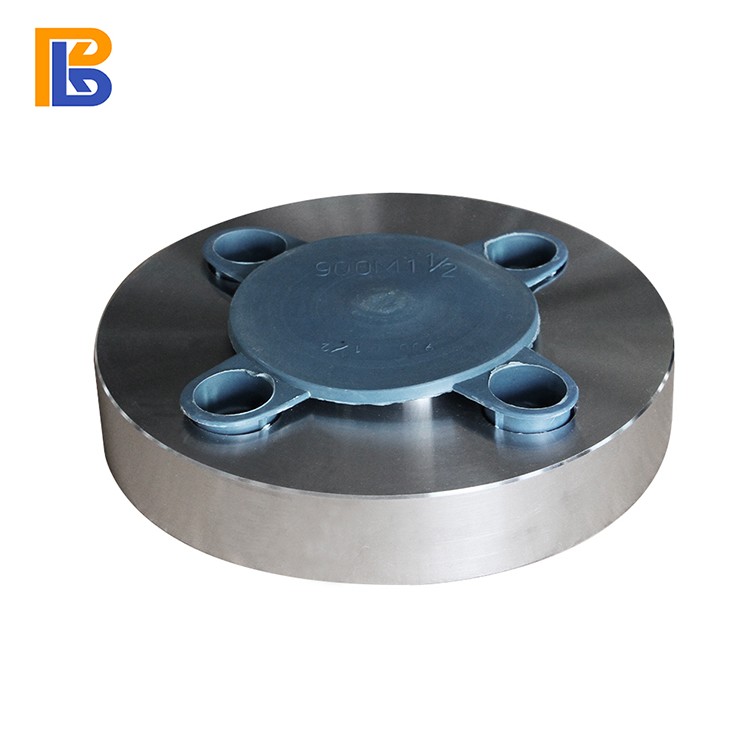

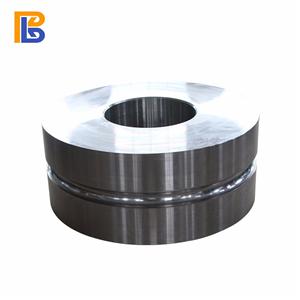

Ring type joint flanges are used to ensure leak proof flange connection at high pressures. A metal ring is compressed into a hexagonal groove on the face of the flange to make the seal. This jointing method can be employed on Weld Neck, Slip-on and Blind Flange.

The Ring Type Joint Flanges:

Model NO.: RTJ flange

Type: Welding Flange

Structure: Round

Sealing Surface: RF

Shape: Circle

Material Grade: 304,316L,321,347H etc.

Specification: TUV, ISO9001, BV, TS, CCS

HS Code: 7307210000

Product description:

1. Standard:

ASME/ANSI B16.5/16.36/16.47A/16.47B, GB9112-9124, GB13402, SH3406, HG20615-20623, HG20592-20605,JB74-90,MSSSP-44,JIS2220-2001,DIN2527/2636/2637/2638/2566/2576/2632/2633/2635/2642/2653/2656/2655, BS1560-3.1, BS4504-3.1

2. Steel Grade/Material:

ASTM:304, 304L, 316, 316L, 316Ti, 317L, 309, 309S, 310, 310S, 347H, 321, 321H, 904L, S31803, S32205, S32760

JIS:SUS304, SUS304L, SUS316, SUS316L, SUS316Ti, SUS317L, SUS321, SUS321H,

DIN:1.4301, 1.4306, 1.4401, 1.4435, 1.4571, 1.4436, 1.4438, 1.4541

3.Size:

DN15-DN1500(1/2"-60")

4.Type:

PL: Plate Flange

WN: Welding Neck

SO: Slip-on Flange/Slip-on Welding

SW: Socket Welding

IF: Integral Flange

TH: Threaded Flange

PJ/SE

PJ/RJ

BL: Blind Flange

LJ: Lap Joint

5. Face:

FF: Flat Face

RF: Raised Face(Finish height of face shall not be no less than nominal pipe wall thickness)

TG: Tongue and Groove(Thickness of lap remaining after machining tongue or groove face shall be no less than the nominal wall thickness of the pipe used)

MFM: Large Male and Female(Finished height of a male face shall be no less than wall thickness of pipe used or 0.25", which is greater. Thickness of lap remaining after matching the female face shall be no less than the nominal wall thickness of pipe used)

RJ: Ring Joint(Thickness of lap remaining after machining the ring groove shall be no less than the nominal wall thickness of pipe used)

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more