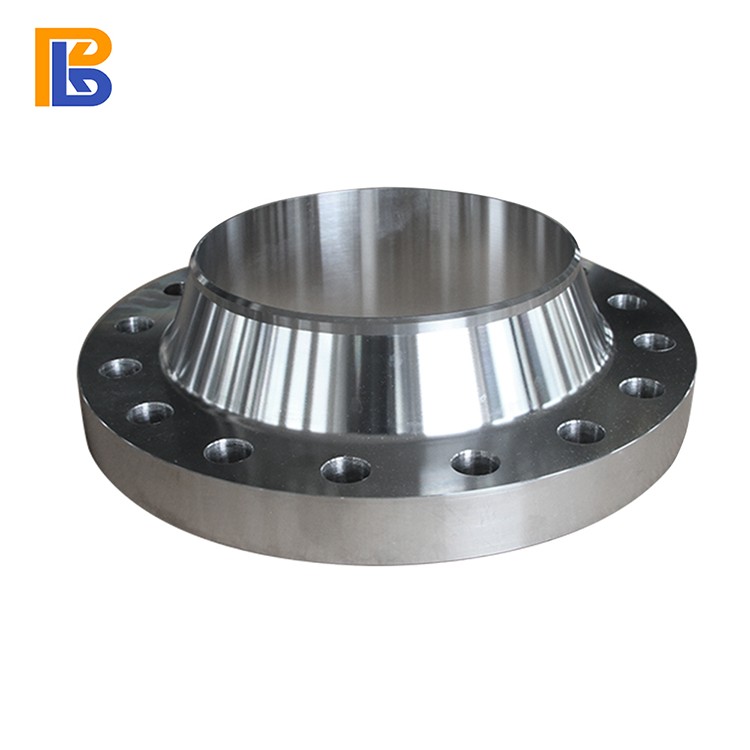

Lap Joint Flanges

- BOBERRY

- China

- 15-30 Days

- 150-200Tons/month

The lap joint flange is a kind of steel part, which is often used as a connection change. The product standard is GB/T 9120-2010.

Flange can be divided into five basic types according to the way of connection with the pipe: flat welding flange, welding flange, thread flange, socket welding flange, lap joint flange. There are many types of sealing faces for flanges. Commonly used are face (RF), concave (FM), convex (M), face (T), groove (G), full plane (FF), ring connection. Face (RJ).

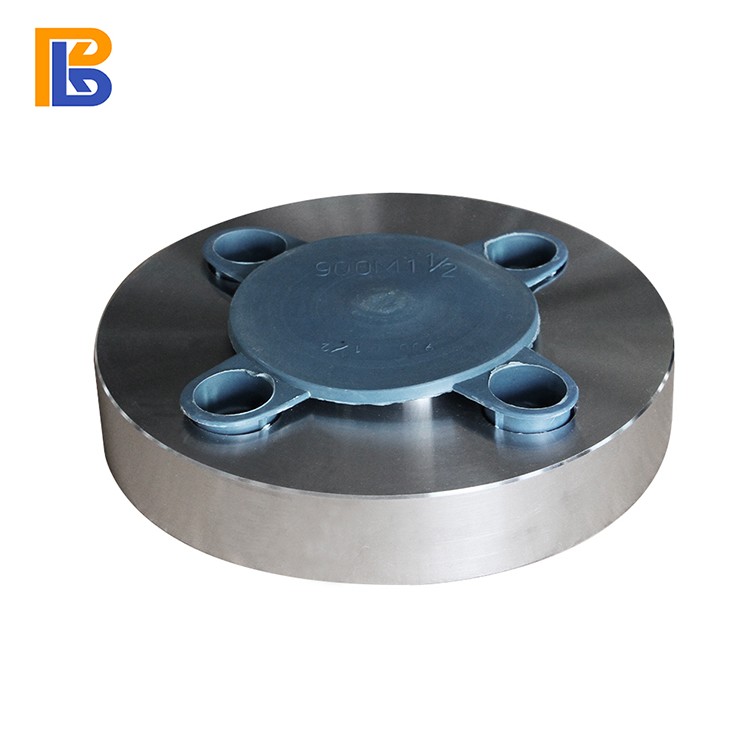

The lap joint flange is actually equivalent to the combination of two flanges.

Common used as a connection is a change in material.

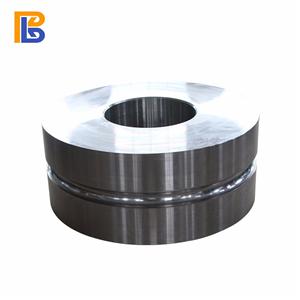

The lap joint flange is sleeved on the pipe end by using a flange, a steel ring, etc., and the flange can be moved on the pipe end. Steel rings or flanges are the sealing faces, and the flanges act to compress them. It can be seen that the lap joint flange is not in contact with the medium due to being blocked by the steel ring or the flange.

The lap joint flange is suitable for the connection and corrosion-resistant pipelines of non-ferrous metals such as steel and aluminum and stainless acid-resistant steel containers.

The lap joint flange is a movable flange. It is usually matched on the water supply and drainage fittings (the most common on the expansion joint). When the factory leaves the factory, there is a flange at each end of the expansion joint, which is directly related to the pipeline and equipment in the project. Connected by bolts.

It is the kind of flange with a looper. It is generally used on pipes, in which case the bolts can be rotated to rotate the pipes on both sides and then tightened. It is convenient to disassemble the pipe. Lap joint flanges are also called loop flanges.

National standard: GB/T9112-2000 (GB9113·1-2000~GB9113·4-2000)

American Standard: ANSI B16.5 Class150, 300, 600, 900, 1500 (WN, SO, BL, TH, LJ, SW)

Japanese standard: JIS 5K, 10K, 16K, 20K (PL, SO, BL, WN, TH, SW)

German standard: DIN2573, 2572, 2631, 2576, 2632, 2633, 2543, 2634, 2545 (PL, SO, WN, BL, TH)

Ministry of Chemical Industry Standard: HG5010-52~HG5028-58, HGJ44-91~HGJ65-91, HG20592-09 Series, HG20615-09 Series

Ministry of Machinery Standard: JB81-94~JB86-94, JB/T79-94~JB/T86-94, JB/T74-1994

Pressure vessel standard: JB1157-82~JB1160-82, JB4700-2000~JB4707-2000 B16.47A/B B16.39 B16.48

Carbon Steel: ASTM A105, 10#, 20#, Q235, Q345B, 16Mn, ASTM A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, ASTM A694 F42, F46, F48, F50, F52, F56, F60, F65, F70;

Stainless steel (Stainess Steel): ASTM A182 F304, 304L, F316, 316L, 1Cr18Ni9Ti, 0Cr18Ni9Ti, 321, 18-8;

Alloy Steel: ASTM A182 F1, F5a, F9, F11, F12, F22, F91, A182F12, A182F11, 16MnR, Cr5Mo, 12Cr1MoV, 15CrMo, 12Cr2Mo1, A335P22, St45.8/III

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more