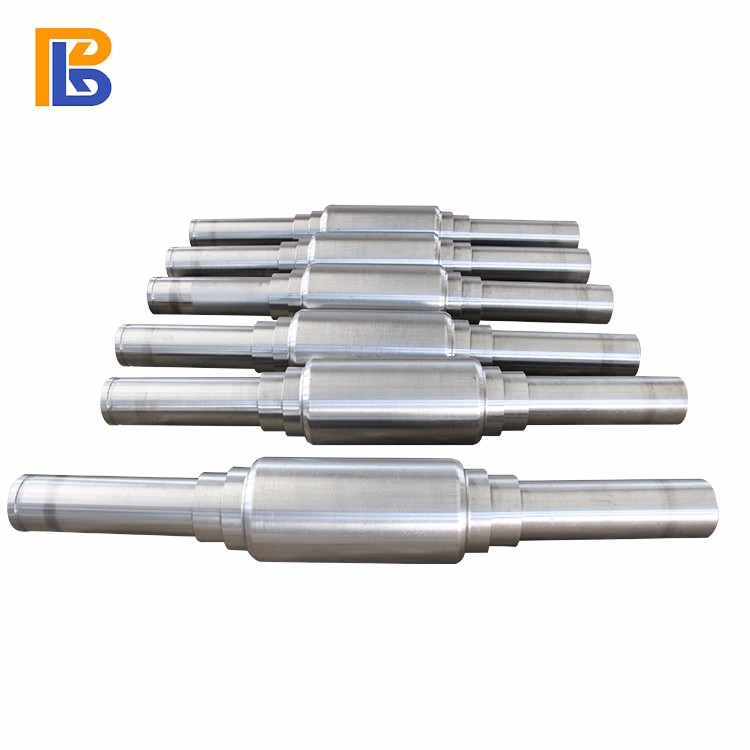

Wind Turbines Motor Shafts

- BOBERRY

- China

- 15-30 days for urgent orders, 30-45 days normally

- 500-1000 Tons/month

Boberry produces Wind Turbines Motor Shafts with dimensional uniformity. And we can produce Wind Turbines Motor Shafts according to customer's drawings.

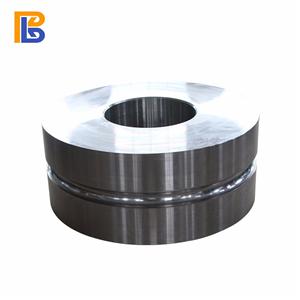

Main material for Wind Turbines Motor Shafts covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Certification: ISO9001, PED ,SGS etc. Material Report for Wind Turbines Motor Shafts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report.

Boberry manufactures wind turbines motor shafts for different industrial applications,according to customer’s drawings.

Forging facilities for Wind Turbines Motor Shafts:

6300T free hydraulic pressure machine

3150T free hydraulic pressure machine

2000T free hydraulic pressure machine

5T electro-hydraulic hammer

3T electro-hydraulic hammer

2T electro-hydraulic hammer

1T electro-hydraulic hammer

750kg electro-hydraulic hammer

560kg electro-hydraulic hammer

Machining facilities for Wind Turbines Motor Shafts:

CNC machines with maximum loading capacity 32 tons

General heavy-duty machines with maximum loading capacity 70 tons.

Gantry milling machines

Deep hole boring machines.

Testing facilities for Wind Turbines Motor Shafts:

Spectrum test machine

Non-destructive test device

Mechanical properties test machine

Metallographic test equipments

Wind turbines motor shaft production Flow

Raw Material: Choose first grade ingot steel, inspect chemical element, confirm achieve requirements.

Forging: Heating to the specified time and temperature,open forging and die forging to the wanted shapes.

Heat Treatment: According Tensile,Yield, Hardness requirements, fully heating.

Machining: Equip horizontal lathe, vertical lathe, CNC lathe, CNC machining center, turning machine,boring machine, milling machine, grinder. Tolerance can hold +/-0.01mm, surface roughness can meet Ra0.4.

Inspect: Every products made a test bar, used for test hardness and mechanical properties. All forging 100% UT inspect.

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more