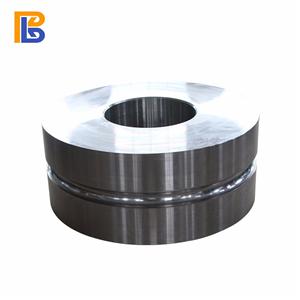

Turning Machined Parts

- BOBERRY

- China

- 15-30Days

- 60-80Tons/month

turning metal parts,Higher accuracy ,stable quality . Turning machined parts ,in generally ,there are two steps , rough turning and finished turning . The purpose of rough turning cut the vast majority machining allowances of machining surface . During rough turning ,there is not the strict requirement for the machining surface ,just keep some machining allowances for semi-finished and finished turning . Rought turning also can find the defect of the inner ,and can dispel the residual stress and thermal deofrmation.Finished machining make sure the tolerance and the surface quality.

turning metal parts regular material:

carbon steel (20#、25#、30#、35#、45#、55#、Q235、Q345、16Mn、50Mn、60Mn、A105 ), alloy construction steel ( 40Cr、25CrMo、30CrMo(4130)、35CrMo、42CrMo(4140)、38CrMoAI、20CrMnMo、40CrMnMo、20CrMnTi、40CrNiMoA(4340)、30Cr2Ni2Mo、34CrNi3Mo、24Cr2Ni2Mo,etc) ,stainless steel ( 304、304L、316、316L、2205、410、1Cr17Ni2、1Cr13,etc) , alloy tool steel (Cr12MoV(D2)、5CrMnMo、H13(4Cr5MoSiV1), etc ) ,etc.

Turning machined parts ,in generally ,there are two steps , rough turning and finished turning . The purpose of rough turning cut the vast majority machining allowances of machining surface . During rough turning ,there is not the strict requirement for the machining surface ,just keep some machining allowances for semi-finished and finished turning . Rought turning also can find the defect of the inner ,and can dispel the residual stress and thermal deofrmation.Finished machining make sure the tolerance and the surface quality.

Turning is used to produce rotational, typically axi-symmetric, parts that have many features, for example holes, grooves, threads, tapers, various diameter steps, and contoured surfaces.

The turning machined parts are widely used to aerospace ,military project , ship building ,petroleum /chemical industry ,energy industry ,transportation ,pressure vessel .....

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more