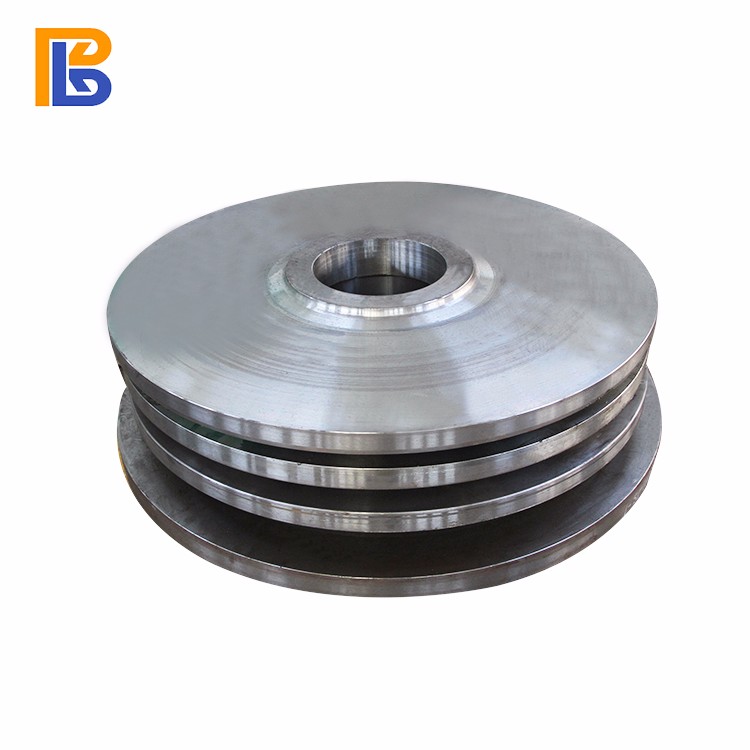

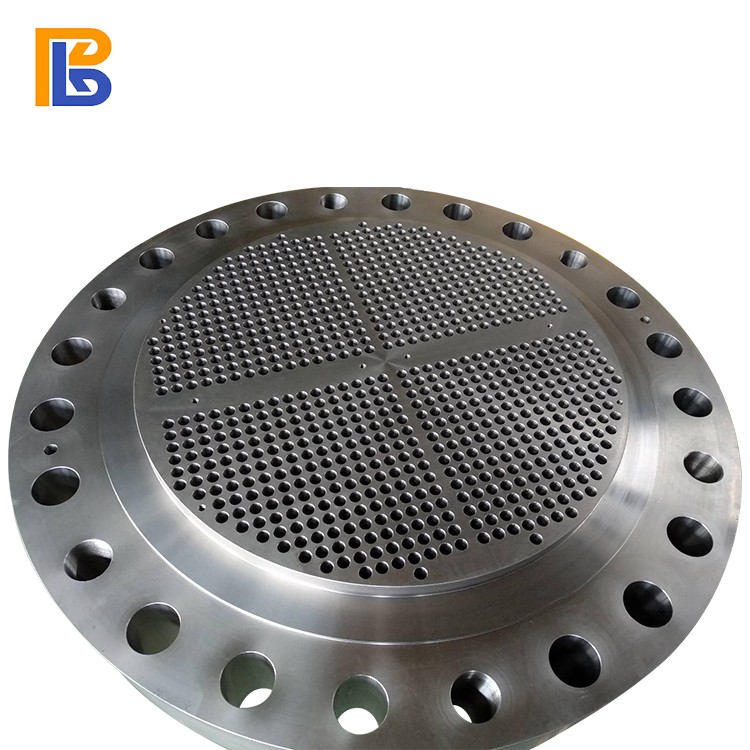

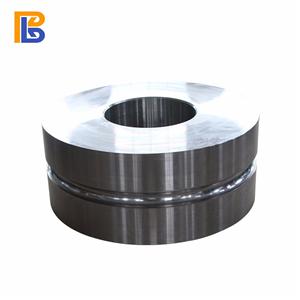

Forged Mill Wheel

- BOBERRY

- China

- 15-30 days for urgent orders, 30-45 days normally

- 500-1000 Tons/month

Forged Mill Wheel series: wheel for railway passenger coach, for railway freight wagon, for locomotive, for metro car, for light rail vehicle.

Forged Mill Wheel characters: High tolerance, High tensile strength, Optimum performance, Heavy Load support.

Forged Mill Wheel main materials cover carbon steel, alloy steel, stainless steel and nickel alloys etc.

Certification: ISO9001, PED ,SGS etc. Material Report for Forged Mill Wheel: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report.

Boberry has Forged Mill Wheel production ability for forging (open forging and die forging) and machining, turning, milling, grinding, boring, drilling, design and programming, and customized service.

Boberry additional servicces to improve the quality and value of our forged parts includes: Quench-and-Temper Heat Treating, Rough Turning, Ultrasonic Testing, Mechanical Testing and etc.

Forged Mill Wheel Process: Raw material inspection →Cutting→ inspection → Preheat → forging → heat treatment → inspection → rough machining → NDT →Testing → finishing machining →NDT →inspection → packing→ Delivery.

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more