Hot Forgings

-

42CrMo4V Forging Parts

42CrMo4V forging parts process: EAF+LF+VD+INGOT+HOT FORGED +HEAT TREATMENT(OPTIONAL)

Email Details

42CrMo4V Forging Parts are widely used for different applications, such as in Machinery, Metalworking, Power Generation, Pulp & Paper Processing and Food Processing etc.

Certification: ISO9001, PED ,SGS etc. Material Report, Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report for 42CrMo4V Forging Parts. -

800H Forged Parts

800H Forged Parts

Email Details

1. Nice appearance of cold-rolled product gloss

2. Nice high temperature strength

3. Nice work-hardening (after processing weakly magnetic)

4. Non-magnetic state solution

5. Suitable for architectural, construction and other applications -

4340 Hot Forging Parts

4340 Hot Forging Parts

Email Details

1. Grade: AISI4340

2. Standard: GB,JIS

3. Certification: ISO9001, PED ,SGS

4. Sample service, MOQ is 1 piece

5. FOB, CIF, DDP delivery

6. By sea, by air and by train transport -

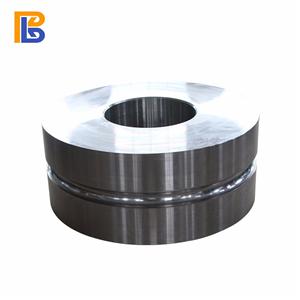

Special Material Forging Parts

Process for Special Material Forging Parts: EAF+LF+VD+INGOT+HOT FORGED +HEAT TREATMENT(OPTIONAL)

Email Details

Boberry produces special material forgings, such as A2 forging parts, Cr12W forging parts etc.

Material Report for Special Material Forging Parts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

Alloy Steel Forgings

There are many kinds of our produced alloy steel forgings, such as D2 forging parts, H13 forging parts and Inconel 625 forging parts etc.

Email Details

Alloy steel forgings include different kinds of alloy steel grades, Special Purpose Carbon Steel, Special Purpose Alloy Steel, Special Purpose Tool Steel, for different applications.

Materials for Alloy Steel Forgings: Carbon steels, stainless steels, duplex steels, alloy steels, nickel alloy steels, non-ferrous materials and Titanium. -

Big Size Forged Shafts

Boberry's big size forged shafts are well accepted by the market. We can produce Big Size Forged Shafts according to customer's drawings. Main material covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Email Details

For example: main shafts, crank shafts used in Machinery, Metalworking, Power Generation, Pulp & Paper Processing and Food Processing etc.

Material Report for Big Size Forged Shafts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. -

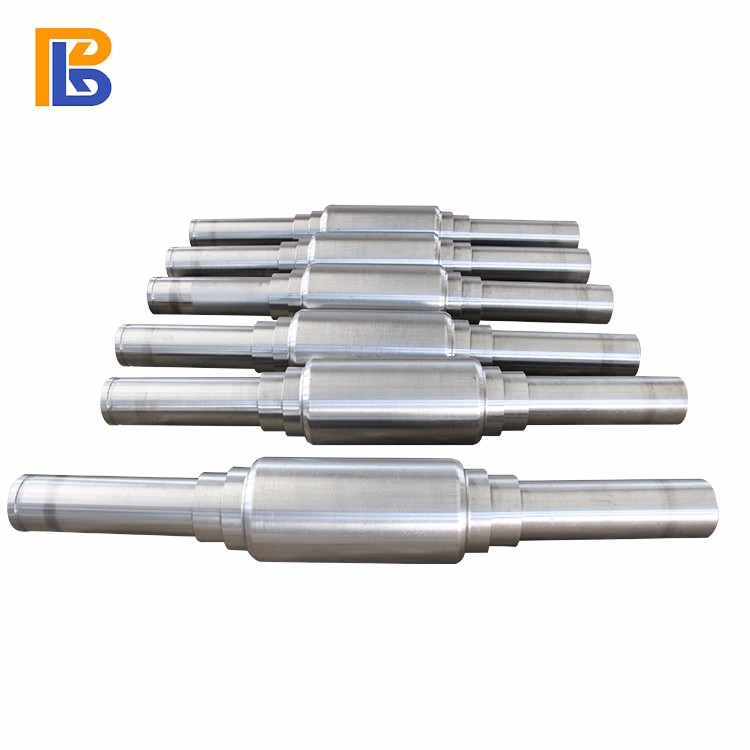

Machined Forged Shafts

Material Report for Machined Forged Shafts: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report. Products include generator shafts, rotor shafts.

Email Details

Boberry has Machined Forged Shafts production ability including machining, turning, milling, grinding, boring, drilling, design and programming, and customized service.

FOB, CIF, DDP delivery for Machined Forged Shafts. By sea, by air and by train transport for Machined Forged Shafts. -

Customized Shafts

Main material for customized shafts covers carbon steel, alloy steel, stainless steel and nickel alloys etc.

Email Details

Certification: ISO9001, PED ,SGS etc. Material Report: Hardness Report, UT/MT Report, Dimensions checking report, and Mechanical Property Test Report for Customized Shafts.

Customized Shafts Sample service, MOQ is 1 piece

FOB, CIF, DDP delivery, By sea, by air and by train transport -

Hot

Metal Forged Step Shafts

Metal forged step shafts is one main product produced by Boberry, including step shafts, main shafts and crank shafts etc.

Email Details

We have Metal Forged Step Shafts production ability from forging to machining, turning, milling, grinding, boring, drilling, design and programming, and customized service.

Our additional services for Metal Forged Step Shafts to improve the quality and value of our forged steel shafts includes: Quench-and-Temper Heat Treating, Rough Turning, Ultrasonic Testing, Mechanical Testing and etc.