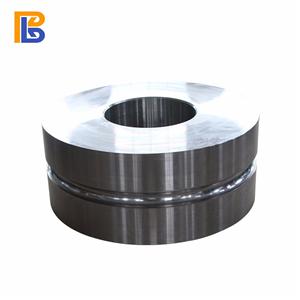

Alloy Steel Forgings

- BOBERRY

- China

- 15-30 days for urgent orders, 30-45 days normally

- 500-1000 Tons/month

There are many kinds of our produced alloy steel forgings, such as D2 forging parts, H13 forging parts and Inconel 625 forging parts etc.

Alloy steel forgings include different kinds of alloy steel grades, Special Purpose Carbon Steel, Special Purpose Alloy Steel, Special Purpose Tool Steel, for different applications.

Materials for Alloy Steel Forgings: Carbon steels, stainless steels, duplex steels, alloy steels, nickel alloy steels, non-ferrous materials and Titanium.

Alloy steel forgings production Flow

Raw Material | Choose first grade ingot steel, inspect chemical element, confirm achieve requirements. |

Forging | Heating to the specified time and temperature, open forging and die forging to shape. |

Heat Treatment | According Tensile,Yield, Hardness requirements, fully heating. |

Machining | Equip horizontal lathe, vertical lathe, CNC lathe, CNC machining center, turning machine,boring machine, milling machine, grinder. Tolerance can hold +/-0.01mm, surface roughness can meet Ra0.4. |

Inspect | Every products mad a test bar, used for test hardness and mechanical properties. All forging 100% UT inspect. |

Smelting facilities for Alloy Steel Forgings:

30T Electric furnaces

30T/60T LF refining furnaces

30T VD/VOD furnace

60T VC furnace

Special smelting equipment( 5T VIM, 200kg VIM, 3T/5T IGESR)

100T large scaled electroslag furnace

Forging facilities for Alloy Steel Forgings:

6300T free hydraulic pressure machine

3150T free hydraulic pressure machine

2000T free hydraulic pressure machine

5T electro-hydraulic hammer

3T electro-hydraulic hammer

2T electro-hydraulic hammer

1T electro-hydraulic hammer

750kg electro-hydraulic hammer

560kg electro-hydraulic hammer

Heating treatment facilities for Alloy Steel Forgings:

Trolley furnace of RTX-9-530KW(8*1.5*1.2)

Trolley furnace of RTX-9-810KW(8*2*1.6)

Trolley furnace of RTX-9-430(6.5*1.5*1.1, 5.5*1.5*1.1)

Vertical furnace of RJ-9-850KW(15M)

High temperature trolley furnace of RTX-12-350KW(3.5*1.3*1.1)

Boberry additional services to improve the quality and value of our Alloy Steel Forgings includes: Quench-and-Temper Heat Treating, Rough Turning, Ultrasonic Testing, Mechanical Testing and etc.

We will always choose the most appropriate process for each forging item, in order to manufacture product of stable quality during the shortest leading time. We guarantee our delivery product has the longest service life of similar products while at low cost to the extremely....more