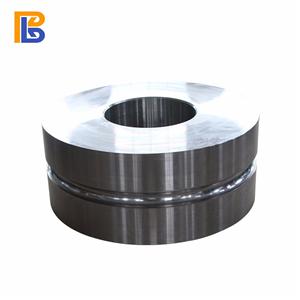

rolled rings

-

Forged Rolling Rings

We are specialized in manufacturing different type of forged rolling rings according to customers' requested, with more than 10 years experience. We have matured manufacturing technology and well exporting experience to overseas,so we can help you handle the difficult matters and help you save the manpower and time cost.

Email Details